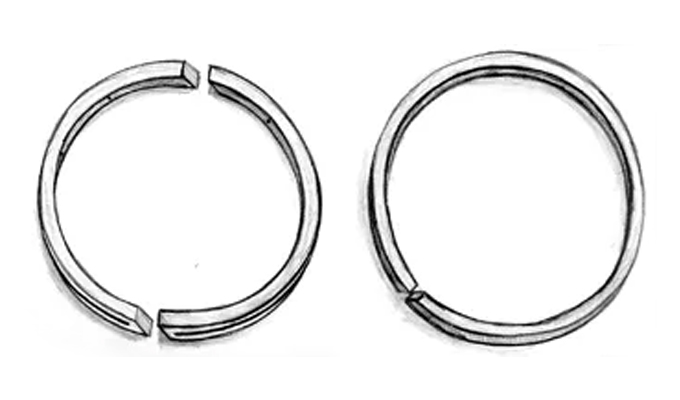

Piston Rings

Piston Rings seal gas pressure to avoid leaking from one side of the compressor piston to the other side. They work by sealing against the cylinder bore and thus compress gas/air.

Rings are available in angle cut, butt cut or step cut designs.

Rings can be manufactured to customer specifications or cross referenced from our extensive library of OEM part numbers.

Ring materials and designs are available for both lubricated and non-lubricated applications. As well as low pressure applications which usually require an expander ring to help energize the ring against the cylinder wall.

Pressure Balanced rings are available for high pressure applications to help relieve pressure associated with the ring riding along the cylinder wall.

Piston Ring/Rider combo is also available for applications where rider bands cannot be installed due to sizing restrictions. Ring/Rider combos can also be used for pistons which have been reworked beyond their recommended clearances and also cannot be machined for rider band installation.

Experienced personnel is on hand to recommend materials and designs for any type of applications and working environments.

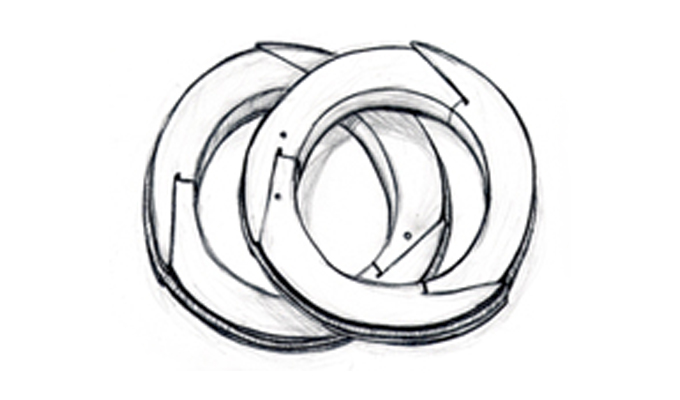

Rider Rings

Rider rings/bands are provided to prevent contact of the compressor piston with the cylinder wall. Such contact could cause problems such as scuffing or more serious and costly problems such as piston and/or liner replacement. Rider rings/bands are normally made of a low friction material such as a Telfon(tm) blend but they can also be supplied in bronze and/or PEEK(tm) for harsh applications with high temperatures.

Riders are available in solid, angle cut, butt cut or step cut designs.

Riders can be manufactured to customer specifications or cross referenced from our extensive library of OEM part numbers.

Solid Rider bands can be manufactured to “on-size” or “oversized” dimensions. Oversized dimensions give the customer the ability to install and recut rider bands to specified clearances.

Wiper Rings

A wiper ring’s main function is to wipe oil from the compressor rod’s surface and contain it within the crankcase or oil source. A narrow wiping edge on the ring “wipes” the oil from the rod and redirects it through radial cut face reliefs in order for the liquid to drain from the cup. A wiper ring’s only function is to wipe liquid from the rod but it can be used in combination with other ring designs to offer wiping and sealing benefits. Wiper rings can be manufactured to OEM specs or to customer specified dimensions. They are available in a variety of materials which are dependent on factors such as compressor rod material, gas being compressed, temperatures and/or working conditions(psi).

Type:

09 Radial Cut Wiper

2-09 2pc Radial Cut Wiper

3-09 3pc Radial Cut Wiper

Scraper Rings

Scraper rings wipe oil from the compressor rod’s surface and contain it within the crankcase or oil source. Scraper rings not only wipe oil from the compressor rod but they also provide a sealing benefit because of their tangential cut. Scraper rings incorporate a deep wiping edge, face reliefs and vent holes to effectively scrape and drain oil from the rod. Scraper rings can be manufactured to OEM specs or to customer specified dimensions. They are available in a variety of materials which are dependent on factors such as compressor rod material, gas being compressed, temperatures and/or working conditions(psi).

Type:

08 Tangent-to-Rod Oil Scraper

2-08 2pc Tangent-to-Rod Oil Scraper

10 Double Acting Tangent-to-Rod Oil Scraper

Rod Pressure Packing

Rod pressure packing consists of a series of mechanical rings that provide a seal against the piston rod so that the compressed gas cannot escape the cylinder. Rod packing rings are precision machined to accommodate specific rod sizes and tolerances set in place by the compressor OEM manufacturer. They can be designed to operate in both lubricated and non-lubricated environments as well as in vacuum or high pressure applications

Rod packing designs and materials vary according to operating and process conditions. Experienced staff is on hand to help you determine the best ring design and material for maximum performance of your packing rings.

Rod Pressure Packing Types:

How to contact us

If you’ve got questions or ideas you would like to share, send a message. For anything more specific, please use one of the addresses listed below.

Quick Contact Form

After we get some information from you, we’ll set up a time to discuss your project in further detail.